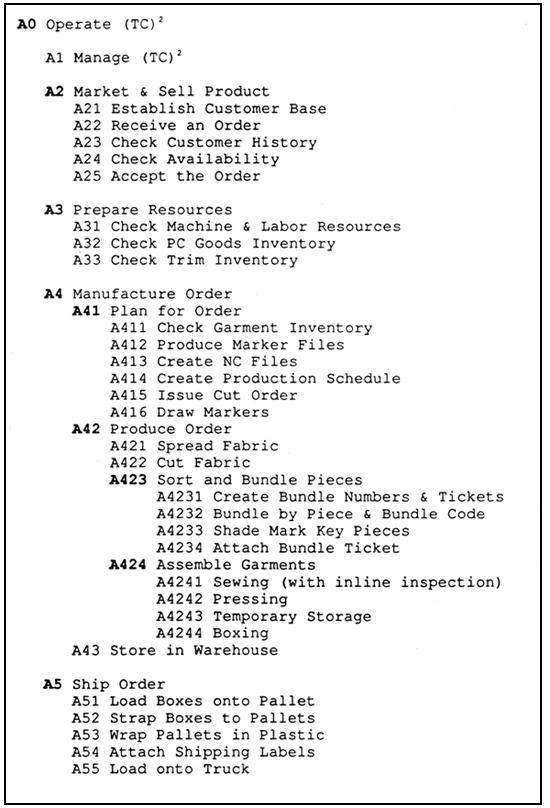

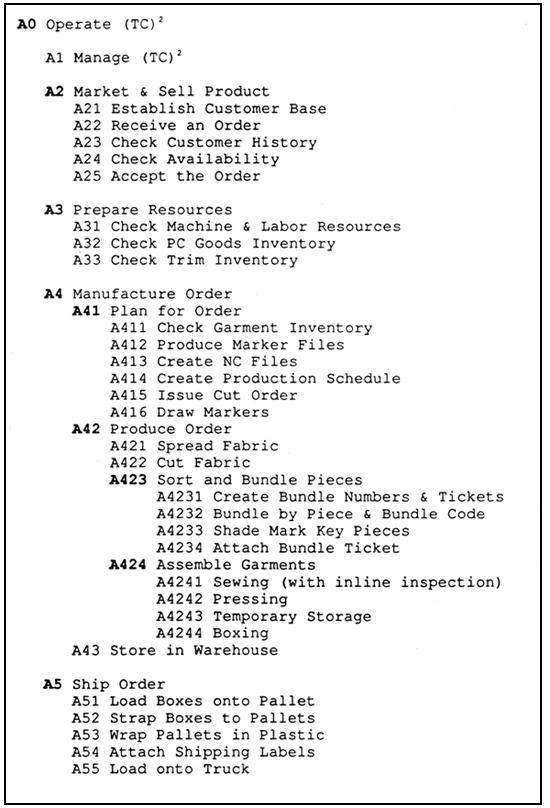

(listed alphabetically)

Accept the Order - Send a confirmation letter to the customer and produce an actual order.

Assemble Garments - Sew, press, and box garments.

Attach Bundle Ticket - Attach the bundle ticket to the bundle.

Attach Shipping Label - Attach label to a pallet of boxes.

Boxing - When a box is filled with the proper mix of sizes, seal it up and send it to the warehouse.

Bundle by Piece & Bundle Code - Organize the cut pieces into appropriate bundles.

Check Availability - Perform a preliminary check of machine and labor availability.

Check Customer History - Make sure customer is legitimate and has good credit.

Check Garment Inventory - Check the inventory and subtract any garments that are already produced from the order.

Check Machine & Labor Resources - Make sure that the type and quantity of machines and labor are available; request more if necessary.

Check PC Goods Inventory - Make sure that type and quantity of Piece Goods are available; order more if necessary.

Check Trim Inventory - Make sure that the type and quantity of trim is available; order more if necessary.

Create Bundle Numbers and Tickets - Use the Leadtec computer to print a bundle ticket and assign bundle numbers.

Create NC Files - Using the marker data, create Numerical Control files for the Gerber cutter .

Create Production Schedule - Create a production schedule that will meet the requirements of the order.

Cut Fabric - Cut the fabric using the NC data.

Draw Markers - Use the plotter to draw a marker required by the cut order.

Establish Customer Base - Find potential customers for your product.

Issue Cut Order - For each item in the production schedule, issue a cut order.

Load Boxes onto Pallets - Stack the appropriate number of boxes onto a pallet.

Load onto Truck - Load the pallets onto the truck.

Manage (TC)2 - Make decisions that serve as constraints to all the functions of (TC)2.

Manufacture Order - Plan, Produce, and store garments for an order.

Market & Sell Product - Establish a customer base for your product and accept orders from those customers.

Plan for Order - Prepare markers, create production schedule, and issue cut orders needed to produce the order.

Prepare Resources - Check availability of machine, labor and inventory resources.

Pressing - Press the garments.

Produce Marker Files - Find an existing marker that satisfies the order requirements, or modify an existing marker, or create a new marker.

Produce Order - Cut and assemble the pieces into garments.

Receive an Order - Obtain a potential order from customer.

Sewing (with inline inspection) - Sew the pieces together, then inspect; if a garment fails inspection at any operation, the operation is repeated.

Ship Order - Prepare an order to be shipped and load it onto a truck.

Spread Fabric - Create a spread using the correct fabric and number of layers for the cut order. Then place the papers marker on the spread.

Store in Warehouse - Store the boxes of garments in the warehouse until the entire order is completed.

Strap Boxes to Pallets - Strap the boxes to the pallet so they will not fall during transport.

Temp. Storage - Temporarily store garments in boxes along the wall beside the pressing station.

Wrap Pallets in Plastic - Wrap the pallet of boxes with plastic to provide extra stability and protection.

(Input, Control, Output, and Mechanism (ICOM) Definitions, listed alphabetically)

Available Styles - The styles of garments (TC)2 can make.

Bad Garments - Garments that do not pass inline inspection.

Bundle Ticket - A ticket, created by Leadtec, that identifies a bundle.

Correct Mix - Each box needs to contain certain numbers of styles, colors, and sizes.

Customer Orders - Potential order for products.

Cut Pieces - The spread, after it has been cut.

Fab. Spec. Trim List - Fabric Specific Trim List; a list of what trim goes with specific fabrics.

Findings (Trim) - Thread, buttons, zippers, etc.

Good Garments - Garments that pass inline inspection.

Labor Request - Request to hire new seamstresses.

Leadtec - Leadtec is a production monitoring and control system.

Manuf. Specs. - Manufacturing Specifications from the Book of Manufacturing Specs kept at (TC)2.

NC Files - Numerical Control Files for the Gerber cutter.

OK1 - Customer is on customer list and has good credit.

OK2 - Resources can be made available to produce the order.

Order - An official, confirmed order.

Paper Markers - A plot of the marker on paper.

PC Goods - Piece goods; cloth.

PO Worksheet - Purchase Order Worksheet.

Spread - Layers of fabric, spread out and ready to be cut.